COMPAIR®

exhaust air and recirculating air

Good air in the house and home!

Who doesn’t want that? The pots steam, the frying pan sizzles and the oven smells delicious. There’s no doubt about it, cooking and baking are great fun!

However, water vapour, odours, grease and pollutants have a negative effect on the indoor air. Cooking smells in the home - especially in open kitchens - are not just annoying. The consequences of bad air can also be unhealthy mould, increased carbon dioxide levels as well as discomfort, headaches and allergies.

Active airing

The need to save heating energy exacerbates the problem. There used to be an unwanted exchange of air through untight windows, roller blind housings and joints in the building envelope. Today, new and renovated buildings are almost airtight. The result: bad air stays in the house or flat – with the consequences mentioned above.

This doesn’t have to be the case though. After all, that’s what extractors are for. They transport the cooking fumes, the so-called vapours, safely out of the home. To ensure efficient ventilation technology, competent planning, aerodynamically optimised components and professional installation are required.

A quick explanation:

exhaust air and recirculating air

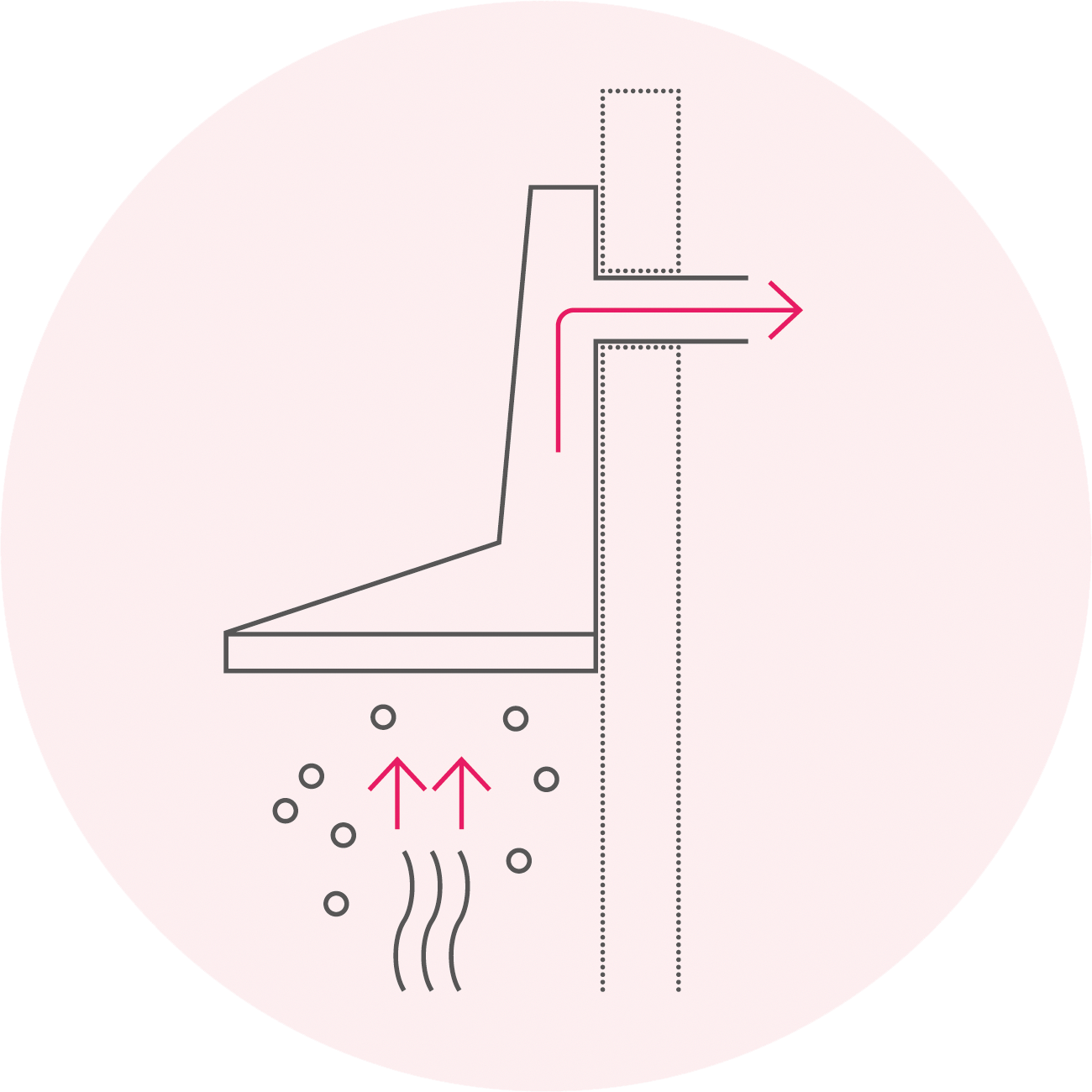

Cooker hoods in exhaust air operation

- The extracted vapours (including moisture and odours) are routed outside.

- Suitable measures are needed to restore the air volume flow to the room.

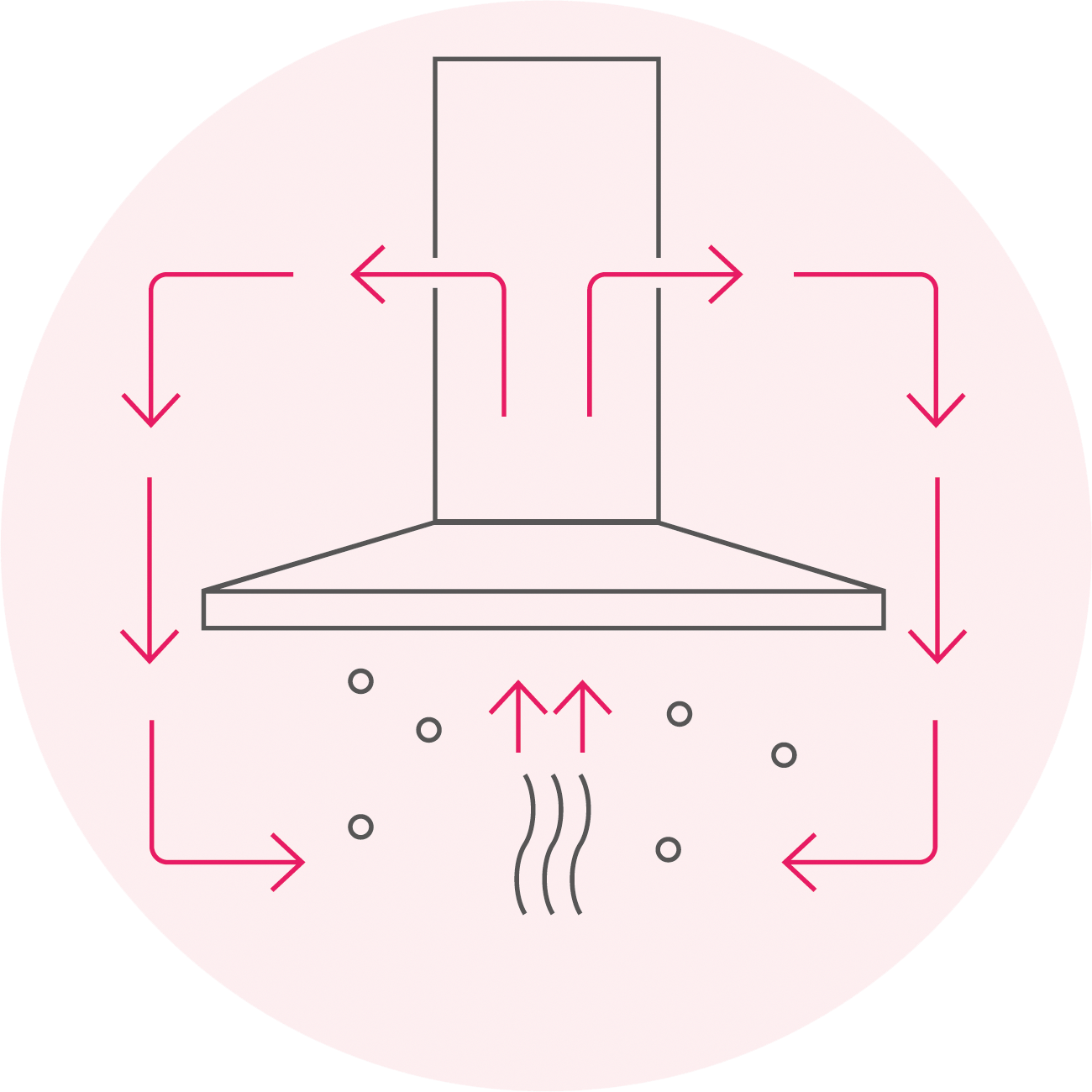

Cooker hoods in recirculating air operation

- The extracted vapours are filtered, and the air is returned to the room.

- The moisture is not removed, so with this extraction system you need a basic exchange of air in the kitchen.

- The removal of odours depends on the effectiveness of the filter system, the maintenance condition and the type of home ventilation.

The video:

exhaust air or recirculating air?

Whatever type of cooker hood you choose, you have to make a basic decision right at the start: exhaust air or recirculating air?

Which type of extractor system works most effectively? What are the advantages and disadvantages of exhaust and recirculating air systems? Are there specifications for passive and efficiency houses? The Steinheimer family gives you some entertaining answers in our video.

By viewing the video you agree that your data will be transferred to YouTube and that you have read the Privacy policy.

Make the right decision

At first glance, a recirculating air unit is the easier choice. This is because the installation and material costs are lower. At second glance, however, the disadvantages are considerable.

The performance of the cooker hood is inferior:

The filters of a recirculating air unit increase the pressure loss, the extractor sucks less air away from the hob at the same power level.

Moisture is not removed::

As the extracted air is returned to the room, the moisture remains in the room. This can cause mould to form at cold patches on the wall.

Grease and odours are not adequately filtered:

The performance of a recirculating air unit depends very much on its filter. Filters that are too small or not replaced often enough reduce the cleaning performance of the extractor. The German consumer organisation Stiftung Warentest shares this view.

Higher power consumption:

To provide the same performance as an exhaust air unit, a cooker hood with recirculating air needs to operate at a higher level. This adds to the electricity bill. Aerodynamically optimised duct systems such as COMPAIR PRIME flow® reduce the pressure loss of an exhaust air solution to a minimum.

Planning with the Naber Guide

Together with scientific institutes, Naber has developed a new study. It assesses exhaust air and recirculating air extractor hoods according to technical, energetic and economic aspects. The results help to plan kitchen ventilation systems, also in energy-efficient homes, in such a way that a sufficiently large air flow volume is captured by the extractor hood during cooking, that odours are reduced as far as possible and moisture damage is avoided. The results are presented in the “Guide to extractor systems for residential kitchens”.

GREENflow recirculating air system in the video

By viewing the video you agree that your data will be transferred to YouTube and that you have read the Privacy policy.

GREENflow, the modular recirculating air filter system for downdraft hoods and hob extractors, safely and efficiently filters out odours and channels the moisture produced during cooking back into the room. In addition, the filter system reduces the overall pressure loss and the noise generated by the extractor system.

The advantages of an exhaust air system

More convenience:

The same performance at a lower level also means less noise in the room. Cooking is more of a pleasure. What’s more, there are no annoying run-on times after cooking to dry the recirculating air filters.

Long-term cost savings:

Purchasing an exhaust system is a little more expensive. In the long term, however, the operating costs of a recirculating air unit are significantly higher if the filters are changed as prescribed. In 2016, Stiftung Warentest already calculated the average annual cost of new filters at 90 euros. The price ranged from 10 to almost 300 euros per year.

Also for efficiency and passive houses:

Innovative wall conducts from Naber such as BIXO Balance® or THERMOBOX reduce the heat loss of an exhaust air solution to such an extent that they are even suitable for level 55 efficiency houses and corresponding passive houses. A recirculating air solution should only be selected for small flats with the efficiency house standard 40.

However, the following applies:

The advantageous exhaust air systems require the right air inflow. A supply air system avoids cold draughts from an open window and significantly improves air throughput and extraction. Important: the supply air conduct has to open and close automatically when the extractor fan is switched on or off. Otherwise, heat escapes to the outside.

It’s what’s behind the extractor that determines performance

Even powerful extractors are slowed down by incorrectly installed or inefficient air ducting and therefore suffer a significant loss of performance. Air ducts, bends, wall conducts and many other products from Naber have been at the forefront of technological development for years. They are optimally aerodynamic and maximally efficient, allowing the air to flow smoothly with little resistance, which saves electricity and is gentle on your nerves thanks to quieter operation.

Whether classic wall hoods or stylish downdraft extractors, whether exhaust air or recirculating air – Naber has the right solution for every system and every room!!