The best tips for planning a cooker hood system

Promising kitchen ventilation systems!

There are many solutions for kitchen ventilation and hundreds of appliance variants. As a professional, you keep your cool! Because at Naber, you’ll find the right component for every planning job for efficient and quiet airflow.

Communicate in time

Discuss the wishes with regard to the extractor with your client and the partners on the construction site (architect / construction company / electrician, etc.) in good time. The HOAI work phase 5 (implementation planning) is ideal. Address the pros and cons of an exhaust air solution and plan the position of the wall conduct.

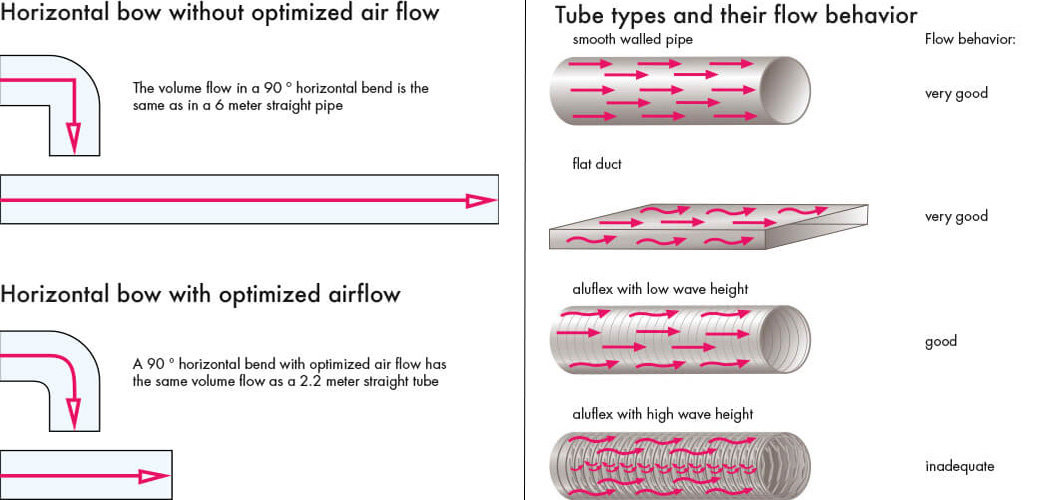

Short routing

Every additional metre of duct and every bend increases the turbulence and brings about pressure losses. Plan the exhaust air routing so it is as short as possible.

The right material in optimal dimensions

Smooth-walled air ducts provide the least resistance to the flowing air. Whether made of plastic or metal, with COMPAIR® from Naber you are always on track. Avoid reductions in the cross section and tight radii of bends.

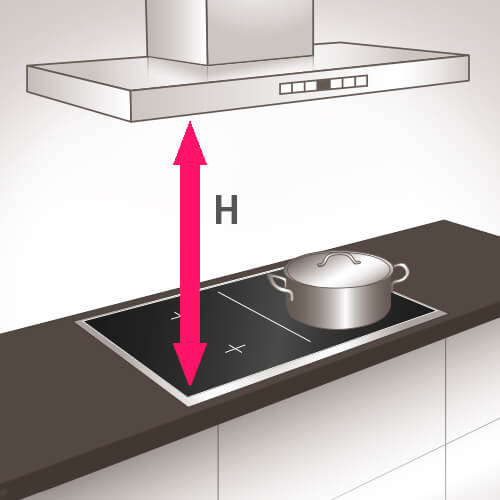

The right hood distance depends on the hood design and is usually specified by the manufacturer.

The right mounting height for cooker hoods

Depending on the design of the hob, a wall-mounted extractor hood requires a minimum distance to the cooking surface. The specifications of the manufacturer are decisive here. Vertical overhead hoods can be installed lower than wall and island hoods. When cooking with gas, the minimum distance is 65 cm. Induction hobs develop less heat. So as to extract the vapours well, the hood should be planned closer to the hob and with a good lateral overlap.

The optimal width of an extractor hood

Take the width of a wall-mounted or ceiling-mounted extractor hood into account when planning rooms and furniture. The larger the distance to the cooking surface, the wider they should be. For 60 to 70 cm wide hobs, a hood width of 90 cm is best. If the hob is 100 cm wide, the hood should be 120 cm wide. Or draw a line with 5 degrees tilt to the right and left, starting from the side edges of the hob.

The width of an extractor hood depends on the distance to the hob.

With the COMPAIR® flow air ducts, you can also effectively control the downdraft technology.

Downdraft and hob ventilation

Downdraft systems and hob ventilation embedded in the work surface extract the rising vapours downwards. Therefore, a high air capacity is needed. The Naber COMPAIR® flow and COMPAIR® bion air ducts are tailor-made for this. And with the COMPAIR STEEL flow® duct system made of metal, you can also lay the exhaust air duct in the floor structure. Recirculating air filter solutions which blow the exhaust air out of the kitchen cabinet harbour the risk of contamination and mould formation due to moisture condensation. An exhaust air solution or Naber COMPAIR® GREENlow is more advantageous. The system guides the vapours through activated carbon filter boxes that can be flexibly integrated into the base area, it eliminates odours even more effectively and, as against unguided air circulation systems, prevents moisture damage and mould formation in the wooden cabinet body. Aerodynamically optimised blades in the ventilation grille, guide vanes in the box and Omega filters minimise pressure losses and flow noise.

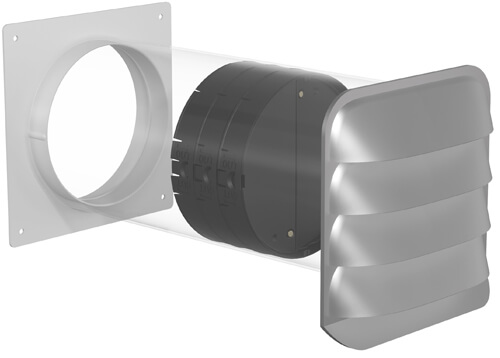

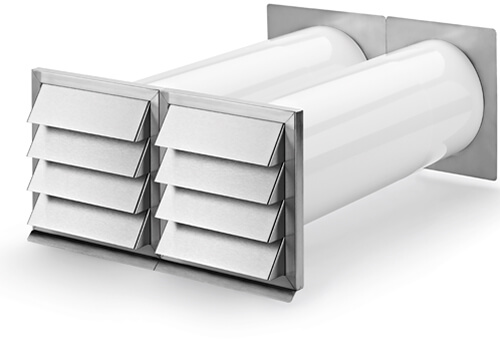

Energy efficient wall conduct

In order to avoid heat loss outside the operating times of the extractor, the energy-efficient heat retention system Naber THERMOBOX is ideal. The BlowerDoor-certified insert in the wall conduct reduces the heat loss by means of three magnetically closing flaps arranged one behind the other. When closed, they form an insulating air cushion. Due to the air pressure of the extractor, the flaps open without electric operation. Thanks to small magnets that hold the flaps in the closed state, there are no rattles even in strong wind. The THERMOBOX is available individually or together with various Naber wall conducts.

Naber wall conduct incl. THERMOBOX

Compliance with requirements for blocks of flats

Flats in multiple dwellings are subject to guidelines and requirements (fire protection regulations, ordinance on firing installations, facade regulations), which are to be observed. Discuss the situation with the architect or building services engineer. This especially applies if the exhaust duct of the extractor hood is to connect to a central installation shaft. In case of old buildings, in the interest of your customer, you should ask the property manager about the existing installation and consult the responsible chimney sweep. Due to the building height of blocks of flats, the installation of a blind for a wall conduct from the outside can be complex. The proximity of neighbouring windows needs to be taken into account so as to avoid odour nuisance.

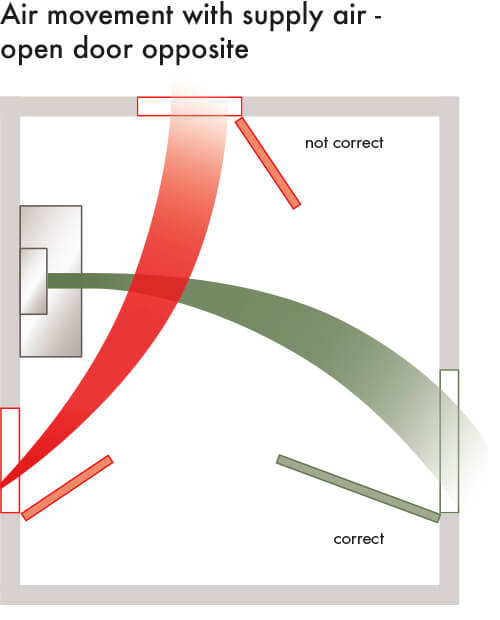

The right movement of air is what counts.

Exhaust air solutions require supply air

The air extracted by the hood has to be replaced. Either via an (electrically) opened window or via a closable supply air duct in the kitchen. It is best if the air supply opposite the hood flows in relatively high up. The cooler air sinks in the room and already takes some of the vapours with it. The air rises vertically above the hob and is removed from the room via the extractor system.

Another alternative is a combined air intake and exhaust air wall conduct, which should be mounted as high as possible in the room. Side windows are not quite optimal for the provision of supply air. Here, the air flow can divert the rising vapours to the side, thus reducing the extraction performance of the hood. If a system for controlled home ventilation and an extractor hood with exhaust air duct are planned at the same time, it makes sense to install a window contact switch. The extractor hood only operates when the window is open. Ideally, the cable for the switch should already be laid by the electrician and not first when kitchen is installed.

Naber wall conduct for supply air and exhaust air

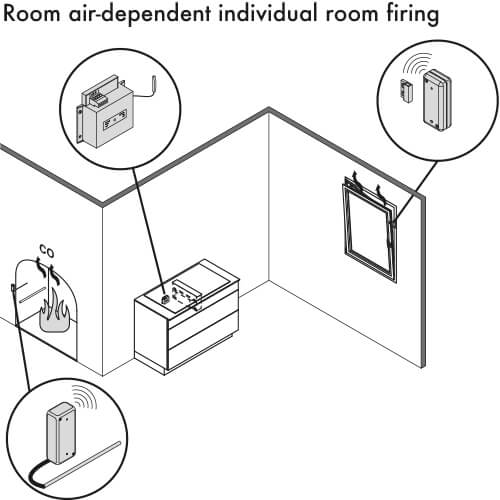

Naber window contact switch for use with single room firing installations.

Is there a heat-producing appliance in the room?

If a room-air-dependent single room firing installation is planned, inform the people involved about the installation of a possible window contact switch. An alternative is a room air-independent fire-place approved by the Deutsche Institut für Bautechnik (DIBt).

Extractor fan and domestic ventilation

The installation of an extractor fan in a flat/house with controlled domestic ventilation requires planning and coordination of the trades. Connecting the extractor fan to the ventilation system is not advisable for reasons of hygiene and fire protection.

There are no legal or regulatory requirements for operation in exhaust air or recirculation mode. As recirculation systems do not remove moisture and only some of the odours, the air exchange rate in the kitchen should be increased in order to safely remove moisture and odours.

If a system for controlled domestic ventilation and an extractor fan with exhaust air ducting are planned at the same time, this is possible in most buildings. If the supply air enters the room via windows, it makes sense to install a window contact switch. The extractor bonnet then only runs when the window is open. This avoids negative pressure in the house. Ideally, the cable for the switch is already laid by the electrician and not just when the kitchen is installed. The alternative is (controllable) outside air diffusers or exhaust air/supply air wall boxes. The heat output in the kitchen area must be adapted to the increased air exchange due to the operation of the extractor hood in accordance with the use. The installation of the wall conduct and the exhaust air duct should be airtight. This is achieved by appropriate sealing and the installation of a THERMOBOX. This is already included in the COMPAIR PRIME flow® wall conduct set.