What makes a good extractor hood?

Promising

kitchen ventilation systems!

Are you looking for the perfect extractor fan for your home? Then our information on the technical details is just right for you.

For an extractor system to do what it is supposed to do, it needs to fulfil certain conditions. Simply placing any appliance above or below the hob is not enough. The good news is that good air in the home is not magic. Here are the most important results of a comprehensive study.

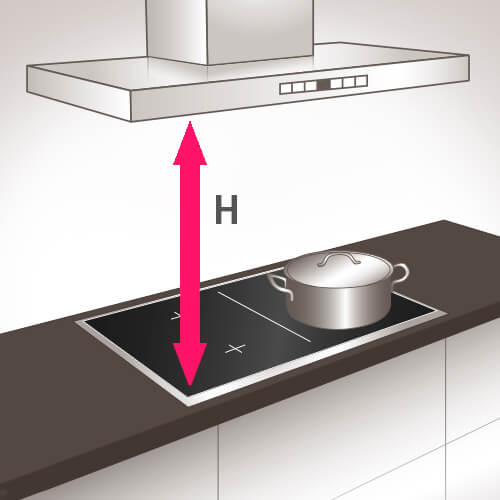

Ideally, the correct bonnet distance should not exceed 50 to 60 cm.

Good air thanks to a high degree of capture

Cooking fumes laden with odours, grease and moisture disappear most effectively when the extractor hood captures as much of them as possible and as little as possible escapes into the room. Wall-mounted bonnets do this job best. Capture is less stable with head-free and island bonnets. Cooktop extractors have to transport significantly more air to achieve the same level of capture in order to draw the rising vapours downwards. This is not completely successful with high pots.

The distance to the hob plays an important role. Ideally, it should not exceed 50 to 60 cm (65 cm for gas hobs).

Reduce odours

Unpleasant odours from cooking and frying are not only an issue in open-plan kitchens. The extent to which they are reduced by the extractor system depends on its capture performance. In exhaust air systems, the captured vapours are directed outside. In recirculation extractor hoods, the reduction is achieved by an activated carbon filter. Success depends on its saturation. The filters must therefore be replaced or regenerated regularly.

In general, the degree of odour reduction depends on the size of the room. It is highest in small rooms and lowest in kitchens open to the living room. This means that the specifications according to the standard may not match the installation situation.

Decay time

In addition to the degree of odour reduction, the decay time provides information about the performance of an extractor system. This value indicates how long the system needs to remove odours. With exhaust air systems, this happens immediately. For recirculation systems, this depends on the fan level and the performance of the activated charcoal filter. With a new filter, it took up to 45 minutes in the test for most of the odours to disappear. With old filters, a decay time of up to five hours was measured, which is hardly realistic in practice. If a domestic ventilation system with a high air exchange rate (1.5 h-1) is used at the same time as the recirculation mode, the time is reduced to between 2.5 and 13 minutes, depending on the appliance. However, this means that the supposed energy advantage of a recirculated air solution is lost.

Pressure losses / noise emissions

When operating an extractor hood in recirculation mode, a large filter volume is required for a good cleaning effect so that the filter filters sufficiently for a long time and the air remains in the filter for as long as possible. Such large filters increase the pressure loss and therefore the amount of air drawn in. At the same time, such appliances are significantly louder.

Grease separation efficiency

Grease is usually separated from the vapour by metal grids. The temperature difference between the hot cooking vapour and the cold metal grille causes the grease to solidify and stick to the grille. Recirculating air systems in particular require a high degree of grease separation to protect the activated charcoal filter that is often installed downstream. This is not achieved by many appliances available on the market. A large proportion of the systems examined in the market study had a mediocre grease separation efficiency of 55 - 80 per cent. In around a quarter of them, this value was below 55 per cent. This means that an extractor hood does not fulfil this function. The value is specified in the manufacturer's documentation. The grease separation efficiency is stated on the mandatory energy label for extractor hoods.

Electrical power consumption / fluid dynamic efficiency

The specified electrical power consumption in watts of an extractor hood says little about its performance. The airflow efficiency, also known as fluid dynamic efficiency, is more decisive. It indicates the ratio of the air volume conveyed and the realised pressure difference to the electrical power consumption and is one of the most important benchmarks for classifying extractor systems according to the EU efficiency label. Flow-optimised devices with EC fans (brushless DC motor) have a significantly lower power requirement for the same air flow rate. The efficiency and length of the air duct system also play an important role here. The maximally aerodynamically optimised COMPAIR PRIME flow® system reduces the pressure loss and therefore also the power consumption required for good air capture.

The fluid dynamic efficiency (airflow efficiency) is an important factor in assessing the performance of an extractor hood.

Maintenance effort

While the maintenance effort for exhaust air systems is limited to occasional cleaning of the grease filter in the dishwasher, the activated charcoal filter also needs to be changed regularly for recirculation systems. Depending on the manufacturer's instructions and cooking habits, this should be replaced at least once a year or more frequently in order to maintain its cleaning performance.

Plasma filter

Extractor hoods with plasma filters are a special type. In them, the exhaust air is ionised with electrical energy. This triggers an oxidation process in which harmful or odour-intensive molecules are destroyed or converted into chemically stable compounds. A downstream activated carbon filter stops this reaction and removes ozone produced during the reaction. Ozone can irritate the respiratory tract and can cause headaches in high concentrations. How well the ozone is neutralised depends on the maintenance condition of the activated carbon filter and the technology used.